Tamper Evident Indexing Heat Sealer

Del recently introduced a new heat sealing system which applies a tamper evident barrier film to many types of containers. Our model SC-18 can be configured with four sealing heads to maximize throughput up to 120 containers per minute.

Model SC-18 Highlights:

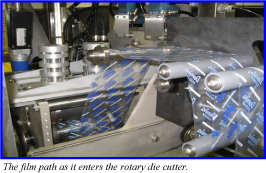

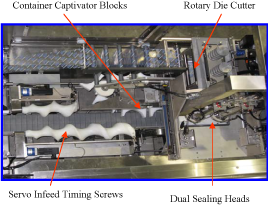

• A servo driven rotary die cutter completely cuts and removes the sealing film patch from the web leaving behind a mere skeleton of film waste, yielding 15% – 20% savings.

• Dual film roll capacity reduces downtime associated with film changes. A splicing table aids the operator during film splicing.

• Variable speed film and container feed with positive alignment of the container with the film patch.

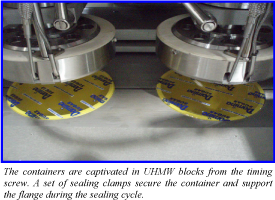

• Fixed position sealing heads with vacuum chucks pick up the film patch and seal the top of the container with minimal film overhang.

• Positive vacuum transfer of the sealing patch from the die cutter to the sealing heads utilizes proven technology.

• Film waste is vacuum conveyed to a remote disp

Significant film savings can be realized by using thinner gauge films. Our vacuum transfer technology makes it possible to run the thinnest films without sacrificing seal appearance and integrity.

Interchangeable timing screws, cradle blocks, die cutter, carriage plate, and sealing heads can adapt to run virtually any shape and size container. Please contact us to discuss your next heat sealing project. We can configure our system to meet your specific needs. ontact us for video, pictures, and drawings of the SC-18!