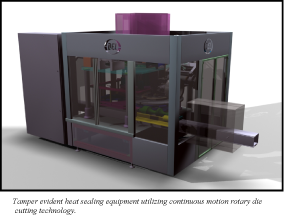

TAMPER EVIDENT SEALING EQUIPMENT

PROPRIETARY TECHNOLOGY LICENSED EXCLUSIVELY TO DEL PACKAGIN

Del Packaging is manufacturing tamper evident heat sealing equipment utilizing proven technology developed over the last 35 years. Our heat sealing equipment relies on a unique technology that has not been available to the public until now. You will be able to acquire this type of equipment for your upcoming heat sealing applications.

What differentiates us from the rest? Other than a small foot print…

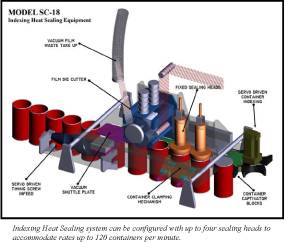

We utilize a hardened rotary die cutter to cleanly cut the patch entirely from the film roll stock. This method produces only a slight gap between each cutout pattern. The film waste is reduced by 15% to 20% compared to traditional sealing equipment. There are additional savings when using a narrower width roll and lighter gauge thickness film.

The die cut pattern is carried across a vacuum drum from the die cutter onto a rotary vacuum turntable. This process is done in continuous motion without losing position.

The sealing heads travel directly above the disk picking up the patch by means of a vacuum assist. The patch is then applied to the top of the container. An optional clamping mechanism is employed for unstable containers with a weak sealing flange or column strength.

A typical film skeleton will look similar to the one illustrated in this picture. Film waste is removed from the equipment through a PVC pipe to a bin for disposal.

The finished result is a precision placed sealed patch with minimal film overhang around the perimeter of the container. The patch is smooth with no jagged serrations for easy overcapping and customer handling.