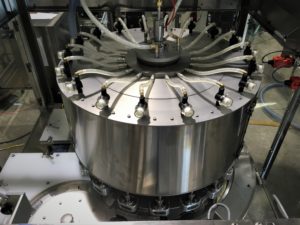

Lid Pluggers | CLPS | Continuous Lid Plugging System

Continuous Lid Plugging System

Continuous motion rotary lid/plug application system featuring an in-feed timing-screw drive to ensure a smooth transfer of the container into the in-feed star-wheel and guide assembly. Cam-actuated chucks are utilized to apply the lid/plug to the container in a controlled, precise manner. A centering star is used (most cases) to precisely align the lid/plug with the container as it is being applied to the container. Available with a 24 or 36 inch turret to meet your production needs.

Applications

| Tappered or straight-walled containers |

| Plastic, metal or composite canisters, vials, and tubes |

| 2″-8″ diameter container and lids/plugs |

| 2″-12″ height containers |

| Ideal for running multiple sizes and heights with change parts |

Specifications

| 60 to 600 lids per minute |

| Stainless steel (non-washdown) construction |

| 220 Volts / 440 VAC / 60 Hertz |

| Designed for multiple heights and sizes (tooling required) |

| 24 or 36 inch turret |

Available Options

| Rotary cap feeder |

| Conveyors (table-top, air, etc.) |

| Coupon / leaflet inserters |

| Stainless steel (non-wash-down) construction |

| Elevator cap sorter feeder |

| Ethernet and communication modules |

| Electrical and control system upgrade |

| Digital height and diameter adjust packages |

| All domestic and international voltages to meet UL and CE requirements |

| Cap detection with reject (fiber optic sensors and/or vision technology) |

DOWNLOADCLPS Cutsheet (contains drawings)

In order to view the attached PDF file, you must have Adobe Acrobat Reader Version 5.0 or higher installed.

A free download is available at: http://www.adobe.com/products/acrobat/readstep2.html.